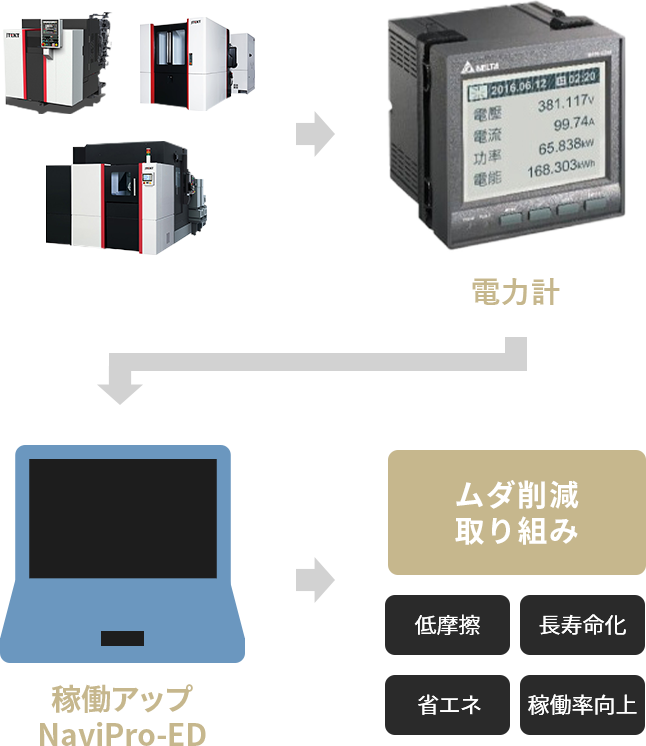

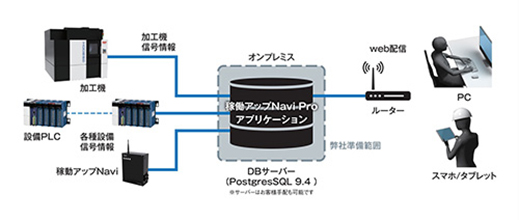

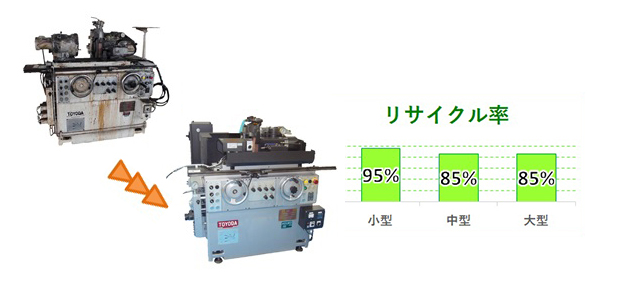

Since the Japanese government pledged to reach carbon neutrality by 2050,

companies have seen a rapid acceleration in demands for carbon neutral initiatives.

JTEKT contributes to our customers' manufacturing with proposals presented by the entire

group so that carbon-neutral initiatives can serve as opportunities for corporate growth.

CARBON NEUTRAL

PAVILION

PAVILION

COPYRIGHT © JTEKT CORPORATION. ALL RIGHTS RESERVED